In the realm of pneumatic applications, precise measurements are of utmost importance, especially in analytical applications. Therefore, understanding valve leak testing methods and their limitations is essential. Keep reading to learn more as we review the significance of leak rates and uncover how they can boost productivity, accuracy, and the lifespan of products, all while reducing the costs associated with subpar quality output.

Skip to a Section

Do zero-leak valves exist? | What are valve leakage rates? |

Why choose a valve with a known leakage rate? | How are leak rates identified and tested? | Watch Webinar

Watch the full webinar any time for an in-depth explanation and application examples.

Do "Zero-Leak" Valves Exist?

In short, no, "Zero-leak" valves do not exist. However, there are valves designed to minimize leaks to a very low level. These valves are called low-leak or zero-leakage valves due to their ability to reduce leakage significantly compared to standard valves.

"Zero-leak" valves use unique design features and seals to minimize leakage as much as possible. These valves typically use advanced sealing materials, such as elastomers or PTFE (polytetrafluoroethylene), AKA Teflon, to create a tight seal and prevent leaks. Additionally, zero-leak valves have multiple sealing points or use new sealing technologies like O-rings or metal-to-metal seals to ensure they don't leak.

Although these valves significantly reduce leakage, they cannot completely eliminate leaks due to factors like wear and tear, changes in temperature, and other environmental factors, which can still cause some leakage over time.

It's important to note achieving zero-leak performance also depends on how the valves are installed, maintained, and used. Regular inspection, monitoring, and maintenance of valves are needed to optimize performance and minimize leakage to the lowest possible level.

Overall, while the term "zero-leak valve" describes valves with extremely low leakage rates, it's essential to understand that completely stopping leaks is almost impossible. However, using low-leak or zero-leakage valves can significantly reduce leakage and make pneumatic systems more reliable and efficient.

What Are Valve Leakage Rates, & How Are They Determined?

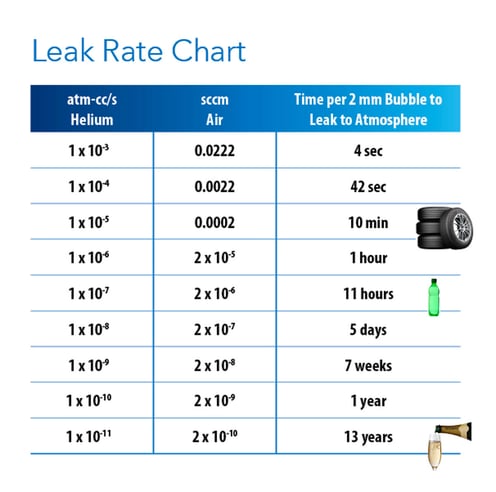

A pneumatic valve leak is when an accidental gas or fluid escapes from a pneumatic valve or its components. The standard way to measure leak rates is using Standard Cubic Centimeters per Minute (SCCM), representing how fast a gas or fluid escapes. To figure out the leakage rate of a valve, you must test it carefully to see how many SCCM it has.

An example of a low leakage rate could be 2x10-8 SCCM, or lower. This means that only a small volume of gas or fluid escapes the system every seven weeks.

On the other hand, a high leakage rate would be significantly greater, potentially ranging in the hundreds or thousands of SCCM or even higher. When the leakage rate is high, this means a large amount of gas or fluid is escaping from the system each minute. Too much leakage can lead to energy waste, decreased system efficiency, reduced pressure, loss of force, and compromised operations - affecting the quality of the product and increasing costs. See Clippard's leak rate chart below for more information.

Why Choose A Valve With A Known Leakage Rate?

- Ultimately, the decision to use valves with known leakage rates depends on application demands, industry standards, and what you intend for the valves to do. Here are some key reasons to consider choosing a valve with a known leakage rate:

-

System Performance

Understanding the leakage rate of a valve helps you better control and predict how well the system will work. By considering the amount of leakage, you can design and calculate the system considering the valve's impact, helping maintain the correct pressures, flow rates, and efficiency.

Energy Efficiency

Energy is wasted in pneumatic systems when leakage occurs. However, by carefully choosing a valve with a documented leakage rate, you can accurately estimate and reduce energy losses caused by leaks - so start choosing valves that prioritize energy efficiency, cost reduction, and environmental sustainability.

Process Integrity

In certain applications, it is essential to maintain specific pressures or keep out contaminants. Valves with known leakage rates allow you to check and ensure the system works correctly. Selecting valves with minimal leakage can prevent issues like pressure drops, contamination, or poor product quality.

Compliance and Safety

Certain industries adhere to stricter compliance and safety standards concerning allowable valve leakage. Utilizing valves with documented leakage rates ensures alignment with these regulations and maintains a safe work environment. This aspect is vital in pharmaceuticals, food processing, and hazardous material handling industries.

Cost Savings

Valves with known leakage rates help us make smart choices about which valves to use, how to maintain them, and when to replace them. By considering the leakage rate, you can choose valves that balance performance, reliability, and cost. Also, if you detect excessive leakage early on, you can fix it quickly, which saves you money by avoiding unplanned downtime and repairs.

System Optimization

Understanding the leakage rate helps you optimize and troubleshoot the system. If you find excessive leakage from a valve, it can be addressed, adjusted, repaired, or replaced, to keep the system running at its best.

How Are Leak Rates Identified & Tested?

It's crucial to distinguish between leak rates and pressure drops over time, as they are different processes. Various methods are employed to assess leaks, each with its advantages and disadvantages. Common techniques include bubble testing, pressure decay testing, and helium detection. You can contact one of our pneumatic experts for more information regarding identifying and testing leakage rates. Contact us!

Watch On-Demand Webinar For More Information

Take a deeper dive into the realm of leak testing and optimize your pneumatic systems with our on-demand webinar.

Resources

Leave Comment