The days of enormous control cabinets and PLC racks full of I/O slices are ending. But what about the countless cable glands and hundreds of cables needed to get back into the control cabinet? Doesn't anyone respect old traditions? I'm glad to say those days are gone, and remote I/O on the machine is here to stay.

So let's review the machine-mounted I/O trend, learn the benefits, and shrink those cabinets for future cost savings and simple maintenance!

Skip to a Section

Why Shrink the Cabinet? | What is Machine-Mounted Remote I/O | Machine-Mounted Power Supplies | Machine-Mounted Ethernet Switches | Summary | Related Articles

Why Shrink the Cabinet?

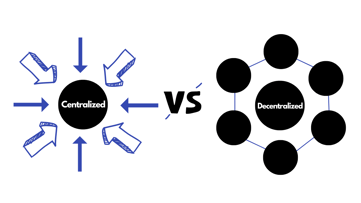

Recently, there's been a trend to use more machine-mounted I/O and other devices in mechanical equipment design. At the same time, as machine design has improved over the years, so has the concept of decentralized systems and their signal and power terminations at the point of operation.

So why shrink the cabinet? Because a smaller control cabinet allows you to save money on hardware while making diagnosing and repairing issues quick and simplified. In addition, most smart I/O blocks now offer the hot-swapping capability to replace a complex sensor or actuator without any configuration needed for the replacement device.

Machine users drive this concept of making machines easier to support after the sale by seeking flexibility and performance when configuring them. So, as machines get more complicated and their maintenance staff requires a higher level of competency, making them easier to diagnose and simple to fix is essential.

Take machine-mounted I/O, for instance. Instead of bringing dozens or hundreds of sensor and actuator cables through wire trays back into a control cabinet, you can terminate those I/O points right at the point of use and then bring one "homerun" or high-density connection cable or even a fieldbus signal back to the processor.

So now that we better understand the "why," let's look at the "what" of these machined-mounted marvels.

What is Machine-Mounted Remote I/O?

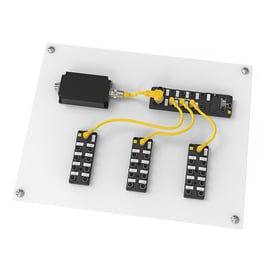

Remote devices connect sensors and actuators, I/O, to the machine controller. Typically, these devices are mounted right at the point of operation to minimize the length of cables required for the electrical signals and power being consumed from the I/O points. Remote devices use standardized electrical connections, like M12, M8, Form-A-DIN plugs, or even Deutsch connectors.

Some devices will utilize a "homerun" cable to route those I/O signals and power back to the central control cabinet. Other blocks have built-in intelligence to convert the I/O signals to fieldbus data and communicate via industry-standard protocols, including Ethernet/IP, ProfiNet, EtherCAT, and many more. Additionally, one more recent subset of these I/O blocks utilizes IO-Link technology.

|

Airline supports brands such as Phoenix Contact, Turck, Omron, SMC, and hundreds of other brands.

|

Machine-Mounted Power Supplies

Adhering to an IP67 degree of protection, these power supplies are ideal for decentralizing supply in the field. Weather-resistant housings protect the devices against dust and water, enabling the IP67 switching grid components to ensure high system availability in harsh ambient conditions. In addition, various device connections provide flexibility during assembly.

Machine-Mounted Ethernet Switches

Nowadays, everything on your machine seems to have an Ethernet port for communicating diagnostic data and I/O status via fieldbus. And now, ethernet switches and hubs are available to mount onto the machine near these devices. The same concept as the block I/O units, these devices allow you to connect your ethernet-enabled equipment to a switch with less cabling and easier replacement if needed. Brands like Phoenix Contact and Turck have great offerings of these devices.

|

Shop Our Inventory Today Airline is an elite distributor of brands, including Phoenix Contact, Turck, and more! |

In summary...

The benefits of remote I/O on the machine are clear: equipment can be located where it is most efficient and easily accessed for maintenance. In addition, saving money on hardware makes the control cabinets smaller and simplifies diagnosing and repairing any issues quickly.

Are you ready to start decentralizing your Remote IO and get it out to the point of operation? If so, let the team at Airline know, and we can help you to shrink that cabinet.

|

We're here to help!

|

Resources

Related Articles

|

What's the difference between an automation distributor and a system integrator? Read this article in Control Design to see what Airline's CEO, Mark Steffens, says about the blurred line between distributors and integrators. |

- How to get Started with IO-Link?

- Industry 4.0 Technologies that pay off now

- IP Ratings Explained

- More Automation blog posts

Leave Comment