Editor’s Note: This blog post (originally published in September 2024) has been updated for accuracy and comprehensiveness.

Every day, pneumatic systems solve a specific problem: how to move, control, and power machines with compressed air. From factory assembly lines to dental chairs, these systems deliver the speed, precision, and safety that our modern processes demand.

But not all pneumatic systems are created equal. And designing or maintaining a pneumatic system can feel like a balancing act. You need speed, precision, safety, and efficiency, without wasting budget or risking downtime. But choose the wrong components or design, and you'll waste money, lose efficiency, and create safety risks. The stakes are high, and small mistakes early on can lead to big headaches later.

That’s why this guide exists: to help give you clarity.

Whether you're designing a new system, troubleshooting an existing one, or simply trying to understand pneumatic technology, you’ll find practical insights to make smarter decisions and avoid costly mistakes.

Let's get into it.

Table of Contents (Jump to a Section)

- What is a Pneumatic System?

- How Does a Pneumatic System Operate

- Key Components of Pneumatic Systems

- Why Pneumatic Systems Matter

- Design Considerations for Pneumatic Systems

- Advantages of Using Pneumatic Systems

- Industrial Pneumatic Applications

- Solutions to Industry Problems

- Pneumatic Industries

- Maintenance & Troubleshooting for Pneumatic Systems

- Additional Resources & Support

Explore answers to common pneumatic questions in our technical FAQ or reach out anytime you need personalized guidance - our experts are here to help!

What is a Pneumatic System?

The word ‘Pneuma’ means 'wind, breath' in Greek, and pneumatics is the science that uses compressed air to transmit energy. Simply put, pneumatic systems use compressed air to perform work. While the early history of pneumatics remains somewhat obscure, the field is typically attributed to Ctesibius of Alexandria. Active in the early 3rd century BCE, he invented several mechanical toys powered by pressurized air, water, and steam.

Today, pneumatic systems are all about harnessing pressurized air to drive various pneumatic components, such as actuators and cylinders, to produce motion. The beauty of pneumatic systems lies in their simplicity and effectiveness, converting force into potential energy that powers mechanical movements. Compressed air, often sourced from the atmosphere before going into a compressed air tank, is the main technology in these systems, making them both reliable and efficient for a wide range of applications.

How Do Pneumatic Systems Work?

The operation of pneumatic systems revolves around the effective management of compressed air or gas (Nitrogen, for example, is commonly used in medical applications) to transmit and control energy.

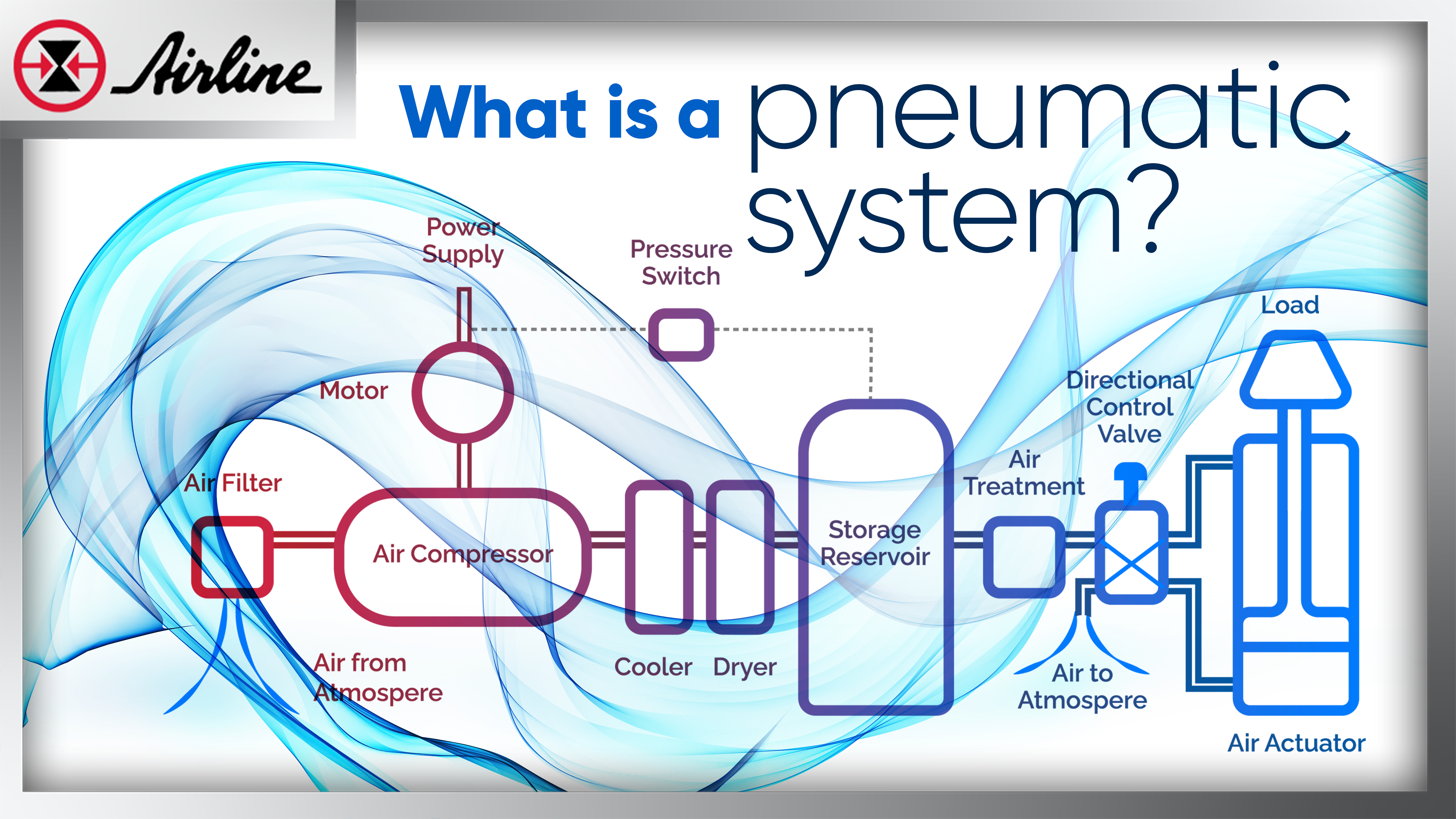

The effectiveness of pneumatic systems hinges on key components that work together seamlessly. While these components may vary depending on the application, the layout below shows an example of a complete pneumatic system.

Simplified Block Diagram for Educational Use Only

|

The journey begins with drawing air through an air filter to remove contaminants. The air is then compressed by an air compressor, which can be powered by diesel or electricity. If electric, the compressor typically requires a motor and power supply. The compressed air is extremely hot and must be cooled by an air cooler unit, then passed through a dryer to remove any water vapor or moisture.

Once purified, the air can be stored in a reservoir tank until needed. The regulation of air pressure is another crucial aspect, achieved through pressure control valves or pressure regulators, which can be adjusted manually or electronically to maintain the desired pressure levels. The air moves effortlessly through the tubing, allowing for efficient operation without restriction.

The air may undergo further filtration and moisture removal before reaching the directional control valve. Valves are critical for manipulating airflow, and in the system above, the air is directed to an air actuator. Air actuators play a pivotal role in this process by converting pneumatic pressure into mechanical movement, driving various pneumatic devices within the system. Or, the air could drive pneumatic cylinders, for instance, which rely on compressed air to drive pistons, enabling both linear and rotary motion. Finally, the exhaust air is returned to the directional control valve and released back into the atmosphere.

Ready to level up? Download our free ISO and JIS-compliant pneumatic symbols chart to learn the standardized symbols engineers use to design and troubleshoot real-world systems.

Why Pneumatic Systems Matter: ROI, Time, and Safety Benefits

Save Money: Real ROI from Pneumatic Systems

Pneumatic systems deliver a strong return on investment (ROI) by improving energy efficiency, minimizing downtime, and reducing maintenance costs. According to Mordor Intelligence’s Pneumatic Equipment Market Report (2025), the pneumatic equipment market was valued at approximately USD 34.99 billion in 2025 and is projected to grow at a 7% CAGR, reaching over USD 49 billion by 2030. This growth highlights the increasing adoption of pneumatic automation, driven by its reliability, cost efficiency, and operational advantages across manufacturing and related industries.

Energy-efficient pneumatic components help significantly cut utility expenses, while automation reduces labor costs and improves product quality. Together, these factors generate measurable cost savings and ensure a quick payback period. As smart monitoring and control technologies are integrated into pneumatic systems, businesses are seeing even greater financial returns within just a few years of investment.

Cost-Effectiveness

A key advantage of pneumatic systems is their cost-effectiveness. They use free atmospheric air as a power source, minimizing ongoing operational costs. Their simple design and straightforward installation further contribute to lower overall expenses. However, effective air leak management is essential, as undetected leaks can lead to energy waste and higher costs. Regular maintenance and monitoring ensure systems remain efficient and cost-friendly over time.

Save Time: Speed and Efficiency Gains

Pneumatic systems deliver exceptional speed and precision, achieving rapid cycle times and millisecond responses essential for high-throughput manufacturing. According to the Institution of Engineering and Technology, digital pneumatic technologies enable real-time monitoring and predictive maintenance, minimizing downtime and driving faster, more efficient operations.

These advances also improve energy efficiency and responsiveness, making pneumatic systems ideal for precision manufacturing tasks that require consistent, high-performance operation.

Reliability

Built for durability, pneumatic components perform reliably even in harsh, dusty, or dirty environments. This robustness makes them a preferred choice in industries such as automotive manufacturing, where high-speed, repetitive automation demands dependable performance.

Routine maintenance and monitoring are key to sustaining efficiency and extending system life. When properly managed, pneumatic systems deliver lasting reliability and productivity gains that translate directly into measurable time savings.

Protect Your Team: Safety and Reliability

Safety is a core strength of pneumatic systems, which are engineered to meet rigorous international standards such as ISO and ANSI. These systems inherently enhance workplace safety by automating hazardous or repetitive tasks, significantly reducing the risk of operator injury.

Pneumatic components integrated with advanced safety controls help minimize risks associated with electrical hazards and equipment malfunctions. According to the 2025 Pneumatic Equipment Market Report, predictive maintenance further strengthens reliability and safety by detecting issues early and preventing sudden breakdowns.

Proper safety practices remain essential. Pressure should always be relieved and loads secured during maintenance or troubleshooting, and Lockout/Tagout (LOTO) procedures must be followed to ensure a secure working environment.

Industry research consistently shows that pneumatic systems contribute to safer, more efficient operations with lower overall risk profiles; all while maintaining high levels of productivity and system performance.

Key Takeaways:

Pneumatic systems advance business performance by generating measurable ROI, accelerating production, and improving workplace safety.

Companies leveraging pneumatic automation hold a competitive edge with results proven in industrial studies and market trends, making pneumatic technology a strategic, cost-effective choice for modern operations.

-1.jpg?width=416&height=277&name=SMC-Products-in-Use%20(12%20of%2013)-1.jpg)

What Are the Main Components of Pneumatic Systems?

- After-coolers, air dryers, and filters for removing impurities

- Pneumatic actuator or cylinder for mechanical motion

- Motor, power supply, or diesel engine to drive the air compressor

- Reservoir tank for storing compressed air

- Pressure regulators to maintain desired pressure levels

- Tubing for transferring pressurized air to various components

- Directional control valves to regulate airflow

All these components contribute to the efficient operation of the system.

Air Compressors

Air compressors are the heart of any pneumatic system, capturing and compressing atmospheric air to provide the necessary air pressure. This compressed air is then utilized to power various pneumatic components, driving mechanical actions across different applications. Proper maintenance of air compressors involves changing filters to avoid contamination and regularly inspecting hoses for leaks and damage. Regular inspections can prevent excessive wear on the air compressor, ensuring efficient and reliable operation.

Innovative technology like the Air Management System (AMS) by SMC can help monitor air consumption and gather data for better maintenance and performance tracking. By keeping the air compressor in optimal condition, the entire pneumatic system can function smoothly, delivering the expected performance and longevity.

Innovative technology like the Air Management System (AMS) by SMC can help monitor air consumption and gather data for better maintenance and performance tracking. By keeping the air compressor in optimal condition, the entire pneumatic system can function smoothly, delivering the expected performance and longevity.

Pneumatic Cylinders

Pneumatic cylinders are integral to converting the energy from compressed air into mechanical motion. These cylinders drive pistons that enable linear or rotary motion, essential for various industrial applications. Pneumatic systems facilitate both high-speed linear and rotational movements, making them suitable for tasks like material transport and processing.

The versatility of pneumatic cylinders allows for their use in a wide range of industrial settings, enhancing efficiency and performance.

Moisture Removers and Filters

As compressed air contains moisture, it can adversely impact the performance of pneumatic systems. To combat this issue, filters, and moisture removers are integral components in maintaining clean and dry compressed air. Methods such as air dryers, aftercoolers, and water separators are employed to control moisture levels. These components work together to keep the air free from contaminants that could clog or damage other system components.

Learn more in our blog post - How to Prevent & Remove Water in Compressed Air

Additionally, filters play a crucial role in preventing contamination of sensitive materials used in life science applications. Proper filtration ensures high-quality production output and consistent results.

Flow Control Valves

Control valves play a critical role in regulating airflow and pressure in pneumatic systems. Flow control valves are crucial to control the airflow accurately based on the requirements of the application. Flow control valves are crucial for metering the airflow rate in pneumatic systems. A flow control valve is different than a flow controller that is on an air cylinder.

Proportional flow-control valves can electronically alter flow rate or pressure, providing better control over the system.

Different types of valves, such as ball valves and pilot valves, are used to control airflow direction.

Angle seat valves can be used to control air on/off functions.

For precise applications, it's critical to select valves with known leakage rates. Learn more in our blog post: Maximizing Valve Performance with Known Leakage Rates

Pressure Regulators

Pressure regulators play a vital role in maintaining the desired pressure levels within pneumatic systems, ensuring optimal performance and protecting system components. These regulators help prevent overpressurization, which can lead to component failure, and underpressurization, which can result in inadequate performance.

Combined filter-regulator units are commonly used for air preparation, ensuring that the air is clean and dry before entering the system.

What about FRLs (Filter-Regulator-Lubricators)?

Modern pneumatic cylinders are often well-lubricated for the component's entire lifespan, eliminating the need for additional lubrication. But in some cases, additional lubrication may be required. Learn more about this in our blog post on Air Line Lubrication.

Air Pressure Amplifiers (Air Boosters)

An unsung hero in the pneumatic world is the air pressure amplifier, also known as the air booster. This device harnesses the energy of compressed air to enhance air force, elevating pressure levels beyond the original source.

Where would you need to use an air pressure booster? If you need a point-of-use air boost: For instance, in a blow-molding application, changing the material from polyethylene to PET requires more pressure. Polyethylene needs less pressure than PET, and you might face insufficient air pressure.

Another issue it solves is if you're running your air compressor at high PSI for a few assets, wasting energy and money. During a facility audit, you might find that most equipment operates at 80 PSI, but some parts need 120 PSI. Instead of keeping the entire plant at 120 PSI, lower the compressor to 85 PSI and use air pressure amplifiers where needed. This saves money by reducing the compressor's PSI while still supporting high-pressure devices.

Learn more in our blog post: How to Increase Your Compressed Air Pressure with Haskel's Air Boosters

How to Design a Pneumatic System

Designing an effective pneumatic system requires careful consideration of several factors, particularly maintaining the required system pressure. Operating within the correct pressure range is crucial; underpressurization can lead to the machine not performing as expected (causing potential safety risks), while overpressurization can cause catastrophic failures due to weakened components. Therefore, it’s essential to design the system within the specifications of the lowest-rated air component, typically 60-80 PSI. This not only ensures safe operation but also enhances the longevity of the system components.

Maintaining pressure within the 60-80 PSI range allows for adjustments based on operational needs without risking component damage. This flexibility is crucial for achieving optimal performance and adapting to different application requirements. Designing with these considerations in mind ensures that the pneumatic system operates efficiently and reliably.

The proper design and installation of air piping is crucial for optimal airflow. Learn more in our blog post: The Do's and Don’ts of Compressed Air Piping Installation

Pneumatic System Examples in Various Industries

Pneumatic systems are incredibly versatile, finding applications in various industries due to their adaptability and efficiency. These systems are particularly beneficial for tasks requiring low expenditure, high speed, force, and accuracy, such as in robotics and automated equipment. Industrial sectors, life sciences, and consumer products all benefit from the reliability and performance of pneumatic systems.

In the automotive industry, pneumatic systems are vital for automation processes and the operation of air brakes. Power tools, which utilize pneumatic systems, are another common application, providing the necessary force and precision for various tasks.

Additionally, vacuum technology, which employs pneumatics, is used in sectors like food and beverage processing, pharmaceuticals, and metallurgy, the branch of science and technology concerned with the properties of metals and their production and purification, for tasks such as vacuum packaging and delicate pick-and-place applications.

Practical Advantages of Using Pneumatic Systems

Pneumatic systems are highly valued in industrial settings for their ability to address specific problems efficiently and cost-effectively. These systems can address moisture accumulation, which can lead to component damage and contamination, by employing various moisture-management strategies.

The following subsections will dive into specific solutions provided by pneumatic systems for common industrial challenges.

Static Electricity Removal with Ionizers

Ionizers are essential in pneumatic systems for neutralizing static charges and enhancing safety and efficiency in sensitive operations. These devices emit ions that neutralize static charges on surfaces, preventing static-related issues such as dust attraction and material handling problems.

Ionizers, commonly used in the printing industry, effectively address static cling caused by friction between rollers and paper. Advanced ionizers, like the Panasonic EF-S1 series, deliver precise ion streams to rapidly reduce static charges. Learn more in our blog post: Best Practices to Remove Static Electricity and ESD in Manufacturing

Electric Actuators for High Accuracy

Electric actuators provide precise motion control, making them ideal for applications requiring high accuracy in pneumatic systems. These actuators offer superior precision and repeatability compared to pneumatic actuators, which makes them suitable for tasks requiring multi-point positioning. The ease of controlling voltage and current in electric actuators ensures consistent speed and force without the need for closed-loop feedback.

Integrating electric actuators with pneumatic systems can significantly enhance performance and reliability in industrial processes.

Creating a Vacuum

Vacuum generators and pumps are critical components in creating low-pressure environments necessary for various applications. These devices utilize compressed air to generate vacuums, which are essential for material handling and packaging tasks.

Vacuum ejectors, for instance, use positive pressure to lift and handle materials efficiently in robotic applications. The ability to create and maintain a vacuum environment is vital for processes that require suction or precise material handling.

Vacuum grippers can also be used on the ends of collaborative robots to handle fragile items, such as glass vials or electronic components. The Bernoulli gripper, for example, creates a gentle and quick vacuum to lift objects without touching or damaging them.

Industries That Use Pneumatics

Pneumatic systems are widely utilized across various sectors due to their efficiency and reliability. From life sciences to industrial automation, these systems enhance productivity and ensure precise control in numerous applications.

The following subsections will explore specific industries that heavily rely on pneumatic systems for their operations.

Life Science

In the life sciences sector, pneumatic systems are indispensable due to their ability to provide clean and dry air, which is crucial for maintaining product integrity. These systems are used in applications like cleanroom processes and medical production, where sterile environments are essential.

Clippard Minimatic recognized the need for miniature pneumatic components and developed their product line specifically for the life science industry. These small and precise components ensure optimal performance in delicate processes.

Clippard Minimatic recognized the need for miniature pneumatic components and developed their product line specifically for the life science industry. These small and precise components ensure optimal performance in delicate processes.

Material Handling

Pneumatics play a vital role in material handling, providing efficient solutions for packaging and conveying processes. They are particularly effective in transporting powders and granular materials, minimizing loss and enhancing delivery speed. By employing enclosed systems, pneumatics ensure that sensitive materials are transported without contamination, thereby maintaining product quality.

This capability makes pneumatic systems ideal for a variety of industrial applications where precise and clean handling of materials is required.

Industrial Automation

Industrial automation heavily relies on pneumatic systems to increase productivity while maintaining precision in operations. These systems are favored for their cost effectiveness, simplicity, and reduced need for maintenance compared to mechanical systems. In processes such as packaging, pneumatic systems ensure precise filling and sealing, streamlining operations and enhancing efficiency.

The quick response times and high accuracy of pneumatic systems make them indispensable in automation tasks that demand reliability and performance.

-1.jpg?width=440&height=293&name=SMC-Products-in-Use%20(9%20of%2013)-1.jpg)

Pneumatic System Maintenance and Troubleshooting

Maintaining pneumatic systems is crucial for ensuring their longevity and efficient operation. Routine maintenance tasks include servicing silencers to prevent clogging, checking air compressor performance, and inspecting and cleaning filters to ensure proper airflow. Regular checks can prevent unexpected breakdowns and maintain the system’s efficiency. Common issues in pneumatic systems include air leaks, insufficient pressure, component wear, and moisture accumulation. Addressing these issues promptly can prevent operational disruptions and extend the system's lifespan.

To troubleshoot pneumatic systems effectively, it’s important to systematically check all connections and replace worn components, especially valves, cylinders, and hoses. If the system experiences insufficient pressure, verifying the functionality of pressure regulators and adjusting them as necessary can help resolve the issue.

Identifying the exact timing of system failures and conducting visual inspections for leaks and damage are key steps in diagnosing problems accurately. Isolating subsystems can also aid in pinpointing the source of issues within the pneumatic system.

The Role of Pneumatic Systems in Modern Industry

Pneumatic systems are integral to modern industrial operations, providing efficient, reliable, and cost-effective solutions across various sectors. Their versatility, coupled with their simple design and maintenance, makes them a preferred choice for many applications. Embracing pneumatic technology can lead to significant improvements in productivity and operational efficiency, making it a vital component of the industrial landscape.

Need help with developing a pneumatic system?

Need help with developing a pneumatic system?

Contact Airline Hydraulics. Our team of technical support personnel specifies, stocks, and supports these devices on a daily basis and can help tailor a solution to your specific needs and budget. Contact us today to get started.

Additional Resources

How to Prevent & Remove Water in Compressed Air

Maximizing Valve Performance with Known Leakage Rates

The 101 of Air Line Lubrication

How to Increase Your Compressed Air Pressure with Haskel's Air Boosters

The Do's and Don’ts of Compressed Air Piping Installation

Lockout/Tagout (LOTO) procedures

Best Practices to Remove Static Electricity and ESD in Manufacturing

Related Products

Air Management System (AMS) by SMC

Leave Comment