Meet the new cobots on the block - the TM S series from Omron Automation. This series of robots is making waves in the industry and revolutionizing how engineers approach cobot deployment. In this blog post, we will dive into what sets the TM S series apart from its predecessors and explore its exciting new features that are pushing the boundaries of what's possible, particularly with its vision capabilities. Let's get started!

Skip to a Section

What is a Cobot? | Key Benefits of the TM S | TM S Series Models | Anatomy of OMRON TM S Series Cobot | Resources

What is a Cobot?

Before we introduce the Omron TM S Series, let's clarify what we mean by a 'cobot.'

Before we introduce the Omron TM S Series, let's clarify what we mean by a 'cobot.'

Unlike traditional industrial robots, collaborative robots are designed to interact with humans in a shared workspace. They’re designed with safety in mind, are more adaptable, and are designed to fit tight spaces.

Industrial robots are less flexible than collaborative robots and require more safety precautions. However, cobots offer more than just safety. They enhance productivity with their problem-solving capabilities and adaptability.

With the ability to take on repetitive tasks, collaborative robots allow human workers to dedicate their time and skills to more complex and creative assignments. This powerful combination of human and robot capabilities has revolutionized numerous industries, improving production efficiency and financial performance.

To dive deeper into the world of collaborative robots, be sure to check out our blog post, "What is a Collaborative Robot?"

Key Benefits of the TM S Series

Omron's TM series and TM S series have redefined what it means to work alongside machines.

What sets the TM S series apart?

The first game-changing aspect of the TM S series is its' enhanced safety design. Omron’s TM S series isn't playing games. With an impressive 31 safety features, including the incorporation of 12 new elements, it sets a new benchmark for cobot security.

But don't forget, additional safety sensors or other provisions may be required based on configured speeds and an application risk assessment. If you need a risk assessment, check out our risk assessment solutions by our machine safety group, MPSA. But don't forget, additional safety sensors or other provisions may be required based on configured speeds and an application risk assessment. If you need a risk assessment, check out our risk assessment solutions by our machine safety group, MPSA. |

Another impressive feature of the TM S series? It has a wide range of available programming methods. The TM S series is crafted to cater to users with varying technical expertise. So, whether you lean towards hands-on guidance or script creation, this range of options promotes operational flexibility.

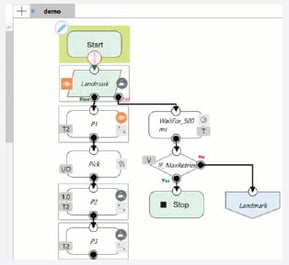

The innovative programming enables users to automate tasks using flow-based software, through a simple click-and-drag approach. With Omron's Operator Platform, designing an application software layout becomes highly intuitive, as visual elements can be dragged and dropped, eliminating the need for trial and error associated with complex coding.

The innovative programming enables users to automate tasks using flow-based software, through a simple click-and-drag approach. With Omron's Operator Platform, designing an application software layout becomes highly intuitive, as visual elements can be dragged and dropped, eliminating the need for trial and error associated with complex coding.

Advanced users can use the script programming method available in both Project and Mode, empowering them to program Cobot projects on the TM S series with precision and efficiency.

Adding to the impressive list of attributes so far, The TM S series' versatility has to be among the stand-out features. Its impressive IP54 rating for key components and joints ensures their resilience in most even harsher conditions. This means the TM S series can perform in sensitive and high-precision manufacturing realms.

So with its IP rating, six rotating joints, six degrees of freedom, a fast-moving camera joint for inspection operations, and an ISO Class 3 Cleanroom rating, the TM S series is ready for almost any environment.

Better yet, some of the best TM features are improved on the new TM S series, including the built-in vision system and landmark positioning tool, allowing seamless relocation to different workspaces and enhancing its versatility for pick and place, machine tending, material handling, palletizing, and a multitude of other applications.

Lastly, meet the new gadget for the TM S, a teach pendant to simplify programming and operation. Its ergonomic design and user-friendly interface make it the command center for the collaborative robot, enhancing the functionality and the interaction with the machine.

TM S Series Models

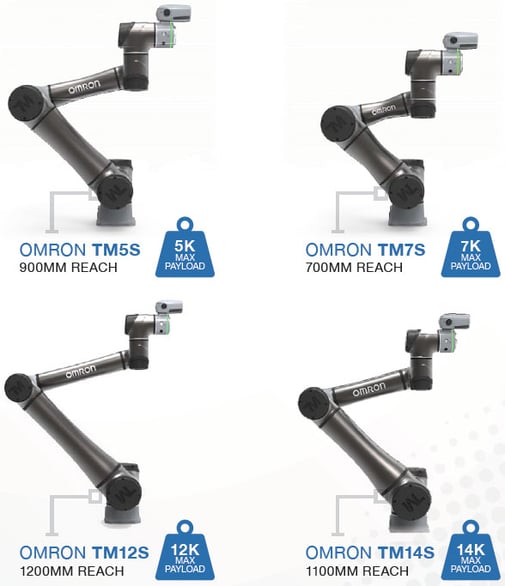

The TM S series offers four different models tailored to meet specific needs. With options for different reach and payload capacities, these cobots are versatile and adaptable to different working environments. Whether you require a DC power mobile robot-compatible model or one that supports EtherNet/IP and PROFINET versions, the TM S series has you covered.

Refer to the image below for a visual representation of the different TM S series models and their capabilities.

- TM5S

- TM7S

- TM12S

- TM14s

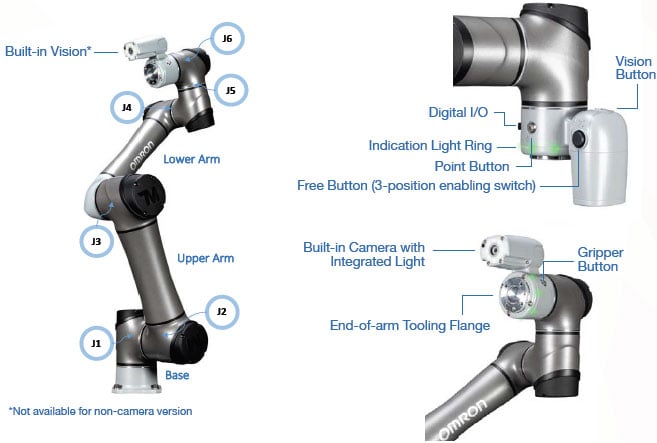

Anatomy of OMRON TM S Series Cobot

While we've covered the standout features of the innovative TM S series, delving into its anatomy can provide a deeper understanding of its impressive capabilities. Take a look for yourself!

The Omron TM S series cobots are built to thrive in diverse industries, spanning from logistics to food and commodities, automotive to digital, semiconductor, and life sciences.

These adaptable cobots showcase their prowess in many tasks - from assembly to palletizing, machine tending to packaging, and seamless pick-and-place operations. They transcend mere upgrades, offering a revolutionary solution that delivers top-notch performance, unrivaled safety features, and a user-friendly interface.

Whether you're an established professional, an eager engineer, or an enthusiast of the robotics revolution, the Omron TM S is a game-changer of innovation worthy of your attention.

Resources

- Discover Omron TM S

- TM S Data Sheet

- Contact us to learn how the Omron TM S can fit into your processes or to schedule a demo at your facility.

Leave Comment