We all want to do more for less, all while maintaining a high-quality standard. That's why principles of lean manufacturing, ergonomics, and 5S methodology should be considered for your manufacturing process. The pressure is on to reduce costs with limited resources, increase productivity, and maintain a safe work environment and ergonomic work environment. So if you're a beginner and want to know what it's all about, you're in the right place. Let's go over what you need to know if you've ever thought about applying lean and ergonomic concepts to your processes.

Jump to Section:

Long-Term Safety Benefits of Lean

What Does Lean Really Mean? (say that 5x's fast)

The concept of lean is all about eliminating waste and is most often used in production and manual assembly environments. The core values look to eliminate excess in every area possible, such as the manufacturing process, physical environment, and even organizational culture. Ideally, instating lean practices should make processes take less time, space, labor, inventory, and money. Becoming lean does not happen accidentally, and should be carefully planned, engineered, and designed on each individual basis to be most effective, but that doesn't mean that you can't start implementing some of the strategies to help your daily workflow be more efficient.

What is Ergonomics?

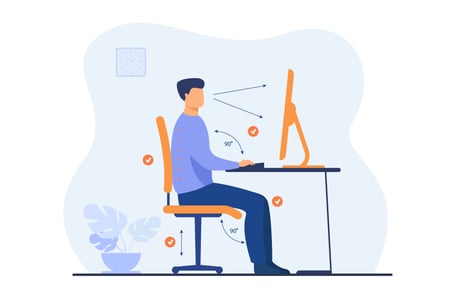

The concepts of lean and ergonomics go hand in hand. Merriam and Webster define ergonomics as "An applied science concerned with designing and arranging things people use so that the people and things interact most efficiently and safely. Also called human engineering." Interacting as efficiently and safely as possible is exactly what Lean wants to do, which is why all of the workstations and equipment in a Lean environment have an ergonomics emphasis.

The application of ergonomics often looks like having daily work environments, like workstations and desks, set up so that everything is within reach, parts are properly presented, directions are clearly visible, the area is well lit, at the proper height, is fully adjustable, and maintains the body's natural alignments and posture whether sitting or standing. This minimizes excess movements and uncomfortable working positions, which increases productivity and reduces ergonomic-related injuries like carpal tunnel syndrome, bursitis, and arthritis.

The 5S Methodology

What is the 5S methodology? Sometimes referred to as 5s or Five S, it lays out a system for a project (or workplace) to become organized and lean, More specifically, 5S is based around five Japanese terms (Seiri, Seiton, Seiso, Seiketsu, and Shitsuke). In English, we translate them to Sort, Set in Order, Shine, Standardize, and Sustain. Let's define each one:

Sort (Seiri)

This means you have sorted through your materials and only kept the essential items you need to get the job done. Everything that's NOT used in the work process is a waste of valuable workspace and should be removed from the area.

Set in Order (Seiton)

After you've ensured you only have the items you need, get them organized with designated places. This organization structure should maximize productivity by having each item handy in a logical place (so you shouldn't have to bend over or rummage through a drawer to find a tool you need!)

Shine (Seiso)

Now that you have a newly organized workspace, keep it clean and tidy! Perform routine tasks like sweeping, dusting, mopping, etc., and keep your tools well maintained.

Standardize (Seiketsu)

Establish standards and processes for getting the job done. This process should include the first three S's, and all of the steps needed thereafter. The process should become standardized for anyone else involved in the job. You can communicate the process to others by using workflows, charts, schedules, and other tools to communicate standards throughout the organization.

Sustain (Shitsuke)

Keep up your good work! Sustain these new lean practices and conduct audits to make sure others are correctly following them too. Keep implementing the 5S methodology, your projects will function much better and your organization will be an easier (and more enjoyable!) place to work.

Long-Term Safety Benefits of Lean

While the efficiency aspect of ergonomics is extremely important to becoming lean, and your bottom line, it may surprise you that the long-term safety benefits of ergonomics will save you more. Workplace injuries regularly equate to 50 billion dollars in direct costs to organizations. The real kickers are the indirect costs of these injuries, like negative public relations, lost productivity, processing and re-training time, increased worker's compensation premiums, and overtime coverage. These costs are often 5x's more than the direct cost of an injury over time.

Musculoskeletal disorders (MSD's) are the largest category of reported workplace injuries, and ergonomics directly combats the leading causes by maintaining the body's natural alignments and positions. Ergonomic workstations save your employee's health, which also saves you money.

If you want to read more about MSD's and see a great Lean and ergonomic accessory, check out our article about Bosch Rexroth's Electric Case Lifters, or download this Ergonomics Guidebook.

In Summary:

Ergonomics will help your employees be healthier, happier, and more productive, saving you money in the long run, and when done right, all of these Lean principles overlap and work together to form an efficient and optimized system that promotes an organized and safe culture.

If you need help putting lean principles into action, Airline Hydraulics specializes in the design, engineering, manufacturing, and installation of both simple and complex Lean work cell systems.

Contact us and we would be happy to answer any thoughts or questions about where you are in your Lean process.

Resources and Information:

- Five Lean Principles You Can Implement Today

- Shop Workstations and Accessories

- Airline Hydraulics YouTube Channel

Don’t miss a post by subscribing to our blog!

If you have a question or comment about this post, please leave it in the comments below.

Contact Us:

Ask your Airline Rep. for assistance with ordering or customizing an order.

800-999-7378

Image credits: Bosch Rexroth, Vecteeze, Freepik

Image credits: Bosch Rexroth, Vecteeze, Freepik

Leave Comment