Conveyors are vital for any modern manufacturing facility, and like all components, they need to be kept clean and well-maintained. But, for washdown applications, (like food and beverage), cleaning conveyors can prove to be a difficult task. Many are complex to clean and have lots of nooks and crannies that are prime for bacteria growth.

That's why QC Conveyors created the HydroClean sanitary conveyor, which boasts a 100% toolless disassembly for easy clean-in-place washdown. In this blog, we'll look at HydroClean and review its toolless maintenance process.

Jump to a Section

What is HydroClean? | Is Hydroclean Sanitary? |

How to use HydroClean | Application Support | Summary

What is HydroClean?

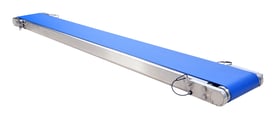

HydroClean (HC200) is a line of sanitary low-profile belt conveyors manufactured by QC Conveyors. The conveyor's standout attribute is its ability to be disassembled and re-assembled without any tools, thanks to its unique pull-pin design. built on a stainless steel frame and can be completely disassembled without tools. Their toolless solution allows for simple maintenance, less wear and tear, fewer stoppages for cleaning, and more efficient conveyor operations.

HydroClean Tech Specifications:

| Widths: 4", 6", 8", 10", 12", 18", 24" |

Lengths: 36" – 18' |

Loads: Up to 120 lbs |

| Speeds: Up to 300 FPM |

Profile: 2.34" |

Fasteners: Metric |

| Construction: Stainless Steel |

Industries: Pharma, Robotics, Packaging, Food & bev, Metalworking, Marking & coding, Brewery, Automation | |

Is Hydroclean Sanitary?

The HydroClean Series feature a sanitary design to minimize opportunities for bacteria growth. In fact, it's one of the only low-profile belt conveyors that are both NSF & BISSC Certified. The conveyor uses hex head fasteners with no exposed threads (these grooves can be notorious for bacteria growth) and has a self-draining frame to ensure no standing water is left behind. Lastly, the V-guided belts are ready for washdown and stainless steel, sealed ball bearings support high speeds up to 300 FPM, and the stainless steel cover protects them during cleaning. Thus HydroClean is ideal for sanitary environments like pharmaceuticals, food, beverage, etc.,

How to use HydroClean's Pull-Pin Design

The HydroClean's disassembly is handled with pull pins along the conveyor’s length, allowing you to disassemble and reassemble without a single tool. Watch our video demo to see how you can remove the sides and guides and flip up the tail to relieve tension on the belt.

The HydroClean's disassembly is handled with pull pins along the conveyor’s length, allowing you to disassemble and reassemble without a single tool. Watch our video demo to see how you can remove the sides and guides and flip up the tail to relieve tension on the belt.

There are pins on the side you can pull to detach it from the stands giving you a path to remove the belt from the conveyor without tools. Once you have the belt off, you can remove both the drive and tail end to clean the outside of the conveyor. HydroClean is an incredibly clean conveyor, perfect for any sanitary application.

Request a Quote from our Support Team

We can help configure and quote products from QC Conveyors and other automation products. |

Summary

Conveyors are essential for a factory line and can make or break the productivity of your production line, which is why it is necessary to ensure cleaning and maintenance are carried out regularly – and can quickly be done without tools! For example, HydroClean, the stainless steel conveyor from QC Conveyors, can be disassembled and reassembled without tools, thanks to its pull-pin design.

Leave Comment