Have you ever seen a robot easily pick up an object without touching it? This is made possible by an incredible invention called “the Bernoulli gripper,” a tool that allows your robot to manipulate an object. Today, we'll take a closer look at this amazing technology, the Bernoulli-type gripper, specifically the ZNC Series by SMC. So grab a notepad and pen, and let's dive right in!

Jump to a Section

6 Types of Robotic Grippers | How Does a Bernoulli Type Gripper Work? |

Meet the ZNC Series by SMC | ZNC Series Advantages

6 Types of Industrial Robot Grippers

A robot gripper is a tool mounted on the end of a robotic arm that allows the robot to hold and release objects. When combined with a collaborative industrial robot arm (cobot), It acts as the robot's hand, enabling it to interact with objects in its environment and allows manufacturers to automate key processes, such as inspection, assembly, pick-and-place, and machine tending. There are various robot grippers, each designed for specific tasks and applications. Different types include:

1. Vacuum Grippers

2. Pneumatic Grippers

3. Hydraulic Grippers

4. Electric Grippers

5. Magnetic Grippers

6. Specialized Grippers

Beyond these main categories, the world of robotic grippers also includes specialized designs tailored to specific industry needs. Each robotic gripper type serves its unique purpose within industrial automation, addressing the varying challenges posed by different products and environments. Whether it's for deploying in tight spaces, operating with precision, or managing heavy loads, there's a gripper designed to meet just about any industrial need.

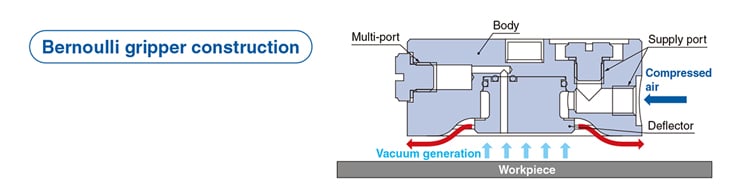

How Does a Bernoulli Type Gripper Work?

The Bernoulli Type Gripper is a specialized robotic gripper that leverages the principle of fluid dynamics to handle objects delicately. Its namesake, the Bernoulli principle, describes the inverse relationship between the velocity of a fluid and its pressure. The gripper uses this phenomenon to lift and hold items with minimal contact, making it ideal for handling delicate workpieces like thin cloths, films, and printed circuit boards.

The Bernoulli Type Gripper is a specialized robotic gripper that leverages the principle of fluid dynamics to handle objects delicately. Its namesake, the Bernoulli principle, describes the inverse relationship between the velocity of a fluid and its pressure. The gripper uses this phenomenon to lift and hold items with minimal contact, making it ideal for handling delicate workpieces like thin cloths, films, and printed circuit boards.

The design includes energy-saving features, vibration suppression, and stoppers for stability and precision. Mounting is easy with different screw sizes and torque specifications. To ensure peak performance, it is highly recommended to use clean compressed air and take into account the workpiece's center of gravity when positioning the gripper. This will effectively prevent any unwanted tilting or potential accidents.

Meet the ZNC Series by SMC

Introducing the groundbreaking ZNC Series by SMC, an innovative Bernoulli gripper that will leave you in awe! Unlike typical grippers, the ZNC Series uses airflow and suction, similar to a high-powered vacuum, to hold onto items safely. It's like your regular gripper, but way quicker and more precise. The magic happens when we supply compressed air into a port. The air sprays out, flows, and as the gripper gets closer to the object, it speeds up, creating vacuum pressure to suck the object, just like a vacuum cleaner!

Introducing the groundbreaking ZNC Series by SMC, an innovative Bernoulli gripper that will leave you in awe! Unlike typical grippers, the ZNC Series uses airflow and suction, similar to a high-powered vacuum, to hold onto items safely. It's like your regular gripper, but way quicker and more precise. The magic happens when we supply compressed air into a port. The air sprays out, flows, and as the gripper gets closer to the object, it speeds up, creating vacuum pressure to suck the object, just like a vacuum cleaner!

It's important to know, though, that it's not a one-size-fits-all tool. It works great with thin materials, circuit boards, and so on, but it won't work with every shape.

What really makes the ZNC Series stand out? Because of its unique vacuum pressure system, it doesn't need to touch the items to move them. This reduces the chances of damaging the items. Plus, it has energy-saving improvements and a high lifting force compared to its predecessor. While it may not outdo all traditional grippers in efficiency, it promises significant energy savings and robust lifting strength. This means that it can be used for long periods without recharging, making it an ideal choice for applications requiring continuous operation. In a race of speed, accuracy, and careful handling, ZNC Series surely beats the other runners in the game!

Video not loading? Watch here.

Advantges of the ZNC Series by SMC

.jpg?width=130&height=119&name=ZNC-B-C1-06%20(002).jpg) Built for very specific tasks, the ZNC series brings together high lifting power, up to 65N, and three diverse body types - resin, aluminum, and stainless steel - offering versatility to fit your needs. It even has stoppers to prevent any slippages, ensuring safer operation. We mustn't overlook the remarkable vibration suppressor feature of the ZNC Series gripper. Not only does it effectively reduce noise levels, but it also creates a more pleasant and comfortable working environment for users.Even more, the ZNC-C model is FDA-compliant and ready to be used in food-related applications. And don't worry about working in dusty or dirty places; the ZNC series has got you covered. By simply supplying clean air, it can block clogging from any foreign matter.

Built for very specific tasks, the ZNC series brings together high lifting power, up to 65N, and three diverse body types - resin, aluminum, and stainless steel - offering versatility to fit your needs. It even has stoppers to prevent any slippages, ensuring safer operation. We mustn't overlook the remarkable vibration suppressor feature of the ZNC Series gripper. Not only does it effectively reduce noise levels, but it also creates a more pleasant and comfortable working environment for users.Even more, the ZNC-C model is FDA-compliant and ready to be used in food-related applications. And don't worry about working in dusty or dirty places; the ZNC series has got you covered. By simply supplying clean air, it can block clogging from any foreign matter.

ZNC Series Resources

The ZNC Series Bernoulli Type Gripper is an impressive technology that has revolutionized how robots pick up objects. Its accuracy, speed, and adaptability have made it popular in industrial settings. As automation and robotics continue to advance, we can expect to see even more innovative grippers like the ZNC Series in the future. Robotic technology has come a long way, and we can't wait to see what the future holds. Remember, we are always here for specification, stock, or application support. Contact us today!

Download the ZNC Data Sheet

Download the ZNC Data Sheet

Leave Comment