Aluminum extrusion is one of the easiest and most versatile materials to build with - using only a few simple hand tools, you can basically build anything! In our previous blog, 3 Easy Ways To Connect Aluminum Extrusion, we introduced you to a few ways to connect aluminum extrusion. In this blog, we will continue to discuss more ways to connect aluminum extrusion along with some friendly reminders of what NOT to do (that we've really seen). Let's get into it!

Skip to a section:

About Aluminum Extrusion | How NOT To Build Anything | Bolt Connector

Polycarbonate Panel | Summary & Resources

About Aluminum Extrusion

The sky is the limit when it comes to building with aluminum extrusion, and Airline has the resources you need to build the project of your dreams. Click here to learn more about how to build anything with aluminum framing. Keep in mind, that most applications come down to knowing two things: Which connector is correct for the application, and how to put it together.

How NOT to Connect Extrusion

You'd be surprised by some of the ways we've seen applications try to connect aluminum extrusion! This material is so versatile to build with due to its adjustability, high structural integrity, and ease of assembly, so any method that hinders those strengths is more of a problem than a solution! Please don't weld your extrusion together.

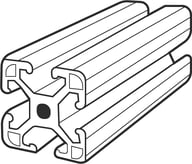

Using a Bolt Connector

The Bolt Connector is one of the strongest ways to connect extrusion together, so we often use this method for joints where strength is a potential concern! You'll need a pre-drilled hole, a barrel, 2 screws with T-nut bolts, and a locating pin. Adjusting the joint is as easy as loosening the screws, and cap covers are available for a clean, aesthetic finish.

Pros: Easily adjustable, extremely strong, cap covers create a clean finish

Cons: Still needs a hole drilled (which could come pre-drilled).

Panel Inserts in Extrusion

A polycarbonate insert can be a great addition to plenty of applications, usually adding an important safety element. The polycarbonate sheet isn't what's structurally joining pieces of extrusion together, but it does fit in between all of the sides to create a useful barrier. Panels can be permanently inserted using Fixed Panel Inserts, but if you feel that the application may change over time, or want the panel to be easily removable, Adjustable Panel Inserts are available as well.

Summary

Now you know how to use the bolt connector, fixed and adjustable panel inserts, as well as how NOT to connect aluminum extrusion. I hope this knowledge helps you in your future applications to keep building anything!

Now you know how to use the bolt connector, fixed and adjustable panel inserts, as well as how NOT to connect aluminum extrusion. I hope this knowledge helps you in your future applications to keep building anything!

Airline Hydraulics has been designing, building, shipping, and installing aluminum framing systems since 1992, and we'd love to answer any questions you have, no matter what stage your project is in.

Resources

More aluminum extrusion blog posts

Shop Aluminum Extrusion

See Framing Systems Examples

Check Out More Blog Posts

Airline's Youtube Channel

Leave Comment