Editor’s Note: This blog post has been updated in January 2024 (originally published in February 2022) for accuracy and comprehensiveness

What if I told you adding an automated guided vehicle (AGV) for end-of-line product transporting can be one of the easiest and most worthwhile things you do as a manufacturer? Let me introduce the AGV company, FRED automation.

Skip to a section:

Meet FRED | Key Features | Applications | Summary | Resources + Info

Meet FRED Automation - The Supply Chain Automation Solution

Meet FRED and his brother, Freddie AGV, your Flexible, Robotic, Environmentally-friendly Delivery vehicle. This is no ordinary machine; it's an Automated Guided Vehicle (AGV) with a special purpose: to make the mundane task of moving objects from point A to point B a breeze.

Picture this: you're in your warehouse facilities or a materials movement automation environment where repetitive tasks are part and parcel of the day. Here comes FRED, designed specifically to ramp up productivity and efficiency, all while cutting down on downtime and minimizing error chances.

FRED AGV Benefits for Warehouse Facilities & Supply Chain Automation

Don't let labor shortages hinder your business goals any longer. Meet FRED and experience the benefits of automation in your operations today. Explore how FRED can help your business thrive during these challenging times and beyond.

Safety

Employee safety is the number one concern. Thankfully, FRED automates some of the most common workplace safety hazards, removing many risks and dangers associated with repetitively moving materials and reducing the required space and need for forklifts and pallet jacks. Blue lights and audible beeps announce FRED's travel direction and presence. Safety sensors scan for objects or people in its path, bringing the AGV to an immediate stop upon detection.

Simplicity

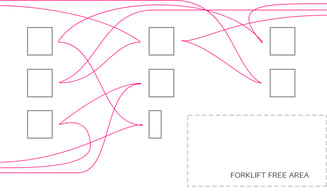

![]() Now, let's talk about navigation. How does FRED find its way? Simple. Lay the magnetic tape on the ground, and FRED will read it. There is no need for software, IT updates, WiFi, GPS, or Bluetooth. This means FRED is not just impervious to hacking, but also incredibly adaptable to changes in paths and processes. Just lay down some new tape, and FRED is ready to roll again. Sounds pretty neat, doesn't it? This ease of integration saves time and resources, making the transition to using FRED smooth and hassle-free.

Now, let's talk about navigation. How does FRED find its way? Simple. Lay the magnetic tape on the ground, and FRED will read it. There is no need for software, IT updates, WiFi, GPS, or Bluetooth. This means FRED is not just impervious to hacking, but also incredibly adaptable to changes in paths and processes. Just lay down some new tape, and FRED is ready to roll again. Sounds pretty neat, doesn't it? This ease of integration saves time and resources, making the transition to using FRED smooth and hassle-free.

Productivity

Labor shortages? Not a problem anymore! FRED is your ideal solution. It's got power, too – it can carry and tow significant weights. But that's not all. Equip FRED with a few extra tools, and it turns into a payload transfer specialist, picking up, transferring, and depositing loads just at the touch of a wireless button within a 100m range. FRED is the ultimate employee by freeing up your actual employees to work on more critical tasks like assembly, improving processes, and overseeing operations, increasing worker productivity. FRED is one of the easiest employees to train and is always safe, efficient, dependable, and on time.

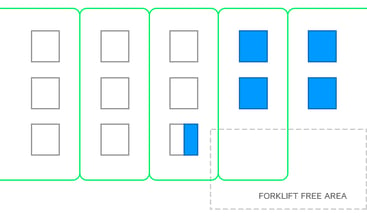

Before

|

After

|

Durability

The engineers behind FRED understand the rigors of moving up to 7,500 lbs of cargo, 25 times a day, 365 days a year. and know that downtime and excessive maintenance is unacceptable. With Heavy-duty steel construction, durable wheels, and the industry's most robust wheel drives, FRED is built like a tank, outlasting forklifts, AMR's, and other AGV's, while requiring less overall maintenance.

Cost-Effective

![]() FRED is a cost-effective solution for businesses facing labor shortages. Its ability to work autonomously helps improve worker productivity and reduce labor costs, and its efficiency leads to increased quality-output, resulting in significant cost savings in the long run.

FRED is a cost-effective solution for businesses facing labor shortages. Its ability to work autonomously helps improve worker productivity and reduce labor costs, and its efficiency leads to increased quality-output, resulting in significant cost savings in the long run.

Additionally, FRED's customizable features make it adaptable to various tasks, eliminating the need for costly specialized equipment. It can be equipped with different attachments and features, making it a versatile solution that can be tailored to various industries. From lifting and materials movement to towing carts and shelves, FRED can be customized to meet the unique needs of any business.

Reduce Downtime

Another significant benefit of FRED is its ability to reduce downtime. FRED operates autonomously, which means it can work continuously, 24/7, without breaks or fatigue. This constant operation reduces downtime and subsequently increases output. Additionally, FRED's design allows it to seamlessly navigate through tight spaces and around obstacles, reducing the chances of collisions and downtime due to technical issues. With FRED, businesses can maintain a steady flow of operations without interruptions caused by labor shortages.

Employee Morale

![]() Using FRED Automation can also improve employee morale. With increased efficiency and reduced tedious, repetitive tasks, employees can feel more fulfilled and motivated, leading to higher job satisfaction. Also, with FRED's safety design, employees can feel at ease walking into work each day, knowing they are less likely to be injured or experience long-term harm due to tedious tasks or materials movement.

Using FRED Automation can also improve employee morale. With increased efficiency and reduced tedious, repetitive tasks, employees can feel more fulfilled and motivated, leading to higher job satisfaction. Also, with FRED's safety design, employees can feel at ease walking into work each day, knowing they are less likely to be injured or experience long-term harm due to tedious tasks or materials movement.

Applications

FRED is at its best when automating your routine end-of-line moving processes, but it can be customized to meet various moving functions. Lifts and conveyor tops can assist in loading cargo onto FRED and unloading it into a gravity rack. Customized carts can be towed, and unique tape tracks can be designed to fit your space and integrate with other automated processes, like stretch wrapping. If you can think of it, FRED engineers can design it!

If you like the idea of automating your moving processes but don't need to haul as much bulk, check out the smaller but still mighty FREDDIE.

Moving Towards the Future

As labor shortages continue to impact businesses worldwide, the importance of solutions like FRED automation will only increase. With its ability to optimize operations, reduce downtime, and minimize human errors, FRED is the perfect solution for any business looking to meet its goals during times of labor shortage.

Meet FRED, and stay tuned to find the right automation solutions for you; FRED is always expanding its production and services offerings.

If you have questions or are interested in demonstrating how FRED could be used in your application, reach out to one of our experts, who are happy to help.

Resources & Information

View FRED Video Demonstrations

Explore More Technically Speaking Articles

Leave Comment