Editor’s Note: This blog post (originally published in June 2020) has been updated for accuracy and comprehensiveness.

You’ve probably heard the expression “running like a well-oiled machine,” referring to something that operates smoothly, especially when it involves many moving parts. But if you own or operate equipment that requires lubrication, you know that this phrase is much more than just a cliché.

Proper lubrication is a critical maintenance practice that directly impacts the life and efficiency of your machinery. Even with this understanding, it’s common to face ongoing challenges that indicate the need for a more effective lubrication solution.

So, if you’re dealing with repeated breakdowns, inefficient lubrication practices, or concerns about safety, it may be time to evaluate your current approach.

In this post, we will review the two main approaches: manual (traditional) lubrication and automatic lubrication systems. Understanding the differences can help you determine which is best for your needs.

In this Post:

Automatic Lubrication System vs. a Traditional Manual Lubrication | Questions to Consider Before Upgrading Your Lubrication Process | Benefits of Automatic Lubrication Systems | How Automatic Lubrication Can Transform Your Operations | Ready to Make the Switch? | Additional Resources

🔍 Explore Automated Lubricators

Automatic Lubrication System vs. a Traditional Manual Lubrication

Manual Lubrication requires maintenance personnel to manually apply lubricant to specific points on machinery at regular intervals. This method involves tracking lubrication schedules, estimating the correct amount of lubricant, and accessing often hard-to-reach points. While effective, it is labor-intensive and prone to human error, leading to potential over- or under-lubrication, missed cycles, and safety hazards.

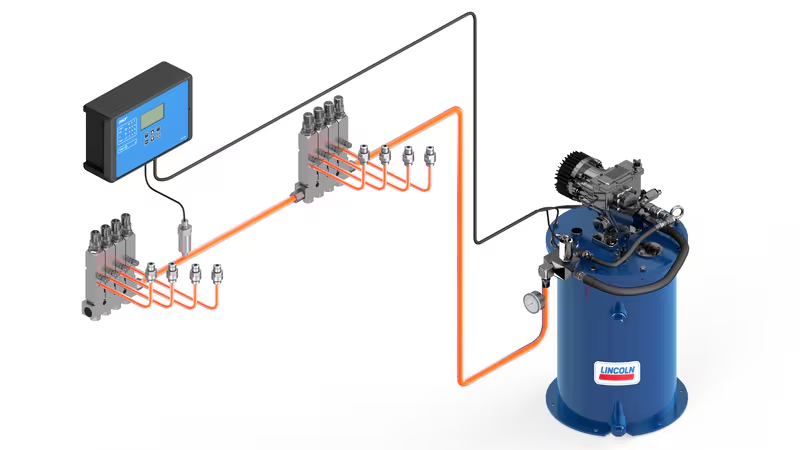

Automatic Lubrication Systems, on the other hand, consistently deliver precise amounts of lubricant to multiple points on your machinery while it is running. This automated process removes guesswork and minimizes human intervention, ensuring optimal lubrication regardless of environmental factors or complex schedules. Automatic systems improve equipment life, reduce downtime, and enhance safety by eliminating the need for personnel to physically access dangerous areas.

Basically, while manual lubrication demands ongoing human effort and carries the risk of inconsistency, automatic lubrication systems provide a reliable, efficient, and safer alternative for keeping machinery in top condition.

Questions to Consider Before Upgrading Your Lubrication Process

If you're still debating which method is best for your applications, consider the following:

- Are we experiencing premature bearing failures and downtime due to inconsistent lubrication?

- Can our maintenance team accurately track lubrication needs?

- Are we confident that the right amount of lubrication is being applied each time?

- Is the safety of our maintenance team at risk due to hard-to-reach lubrication points?

- How much production time do we lose due to manual lubrication shutdowns?

- Could our maintenance team be used more effectively if lubrication was automated?

If the answer to any of these questions raises concerns, it might be time to consider an automatic lubrication system.

Benefits of Automatic Lubrication Systems

Automatic lubrication systems can be a game-changer for businesses relying on complex machinery. Here are some of the key benefits:

Reduced Equipment Downtime: Keep your equipment running while it's being lubricated, reducing downtime and avoiding costly production interruptions.

Improved Equipment Life: Deliver precise amounts of lubrication at the right intervals, preventing both over- and under-lubrication and extending bearing life.

Increased Productivity: Lubrication is performed while equipment is operating, eliminating the need to stop production for manual lubrication.

Cost Savings: Use the right amount of grease each time, minimizing waste and reducing lubrication costs.

Enhanced Safety: Eliminate the need for maintenance personnel to access hard-to-reach areas, reducing the risk of accidents.

How Automatic Lubrication Can Transform Your Operations

Many companies struggle with lubrication issues, leading to costly unplanned shutdowns and high maintenance expenses. Switching to automatic lubrication reduces equipment downtime, minimizes manual intervention, and ensures consistent, precise lubrication—regardless of weather conditions or equipment complexity.

Imagine a maintenance-free lubrication process that works seamlessly in the background while your machines continue to operate at peak performance. The result? Lower maintenance costs, fewer disruptions, and a safer workplace for your team.

Ready to Make the Switch?

If you're tired of costly maintenance headaches and want a more efficient way to protect your equipment, it's time to consider an automatic lubrication system. Explore automated lubricators or contact our team today to find the right solution for your specific needs.

We’re here to help keep your machines running like a well-oiled—and well-lubricated—machine.

Additional Resources

- Explore Automated Lubricators

- Fluid Cleanliness Solutions

- Shop Lubrication Equipment Accessories

- Custom Lubrication & Hydraulic Systems

Leave Comment