Air pressure regulators are a critical component that ensures pneumatic systems' safe and efficient operations. However, choosing the right type of regulator can be challenging, especially if you're unfamiliar with its numerous types and features. In this blog, we'll explore three specific flow features of air pressure regulators; relieving, right-to-left, and regulators with backflow functions. And although the descriptions sound similar, their operation and applications are very different. Demystifying these three air pressure regulators will help you configure the correct components for your application, so keep reading.

Shop Filter/Regulator Combination Unit

Skip to a Section

Relieving Regulators | Right-to-Left Regulators | Regulators with Backflow Function | Combining the Features | How to Choose a Pressure Regulator

Relieving Regulators

Relieving regulators are the most common type of pneumatic regulator. They are designed to maintain pressure at a preset level and are adjustable through a knob or screw. The regulator's internal valve modulates in response to changes in flow demand, allowing more or less air to pass downstream, as required to maintain the set pressure.

In some applications, downstream pressure may rise above the setpoint. This rise can occur due to an outside mechanical influence in the circuit or thermal expansion in a hot storage tank. In such cases, a relieving regulator can vent the excess pressure, maintaining the setpoint. The relief flow passes from the outlet port, back through the relief port, and into the atmosphere.

Non-relieving regulators are similar to relieving regulators but cannot vent pressure. They are mainly used for gases other than air that may create hazards if vented into the surrounding atmosphere (even inert gases such as Nitrogen can cause asphyxia in an enclosed space). Or, they may be used inside gasketed enclosures, where pressurization would cause a rupture disk to burst.

Non-relieving regulators can be challenging to set up because if the regulator is inadvertently adjusted a few psi too high, excess pressure must be vented by an external path (i.e., disconnecting a downstream line), which can be tedious. For this reason, a relieving regulator should be the default choice for compressed air.

Right-to-Left Regulators

Most pneumatic circuits are plumbed with the incoming air supply on the left side. However, there are situations where it's more practical to plumb in the opposite direction. This situation may be due to the location of existing air supply lines, space constraints, or other factors. The regulator is rotated 180 degrees in those cases, with its inlet port on the right side. Then, the gauge must be moved to the opposite face of the regulator to be viewed from the front. A right-to-left regulator is factory-configured for such applications.

Most pneumatic circuits are plumbed with the incoming air supply on the left side. However, there are situations where it's more practical to plumb in the opposite direction. This situation may be due to the location of existing air supply lines, space constraints, or other factors. The regulator is rotated 180 degrees in those cases, with its inlet port on the right side. Then, the gauge must be moved to the opposite face of the regulator to be viewed from the front. A right-to-left regulator is factory-configured for such applications.

Regulators with Backflow Function (Reverse Flow Regulators)

Regulators with backflow functions, also known as reverse flow regulators, are used in applications where pressure downstream of the regulator must be exhausted during regular machine operation or system shutdown. An integral bypass check valve permits air to flow backward through the regulator when inlet pressure is removed. This type of regulator can be installed between a cycling valve and an actuator, allowing the actuator to extend and retract with two different pressures.

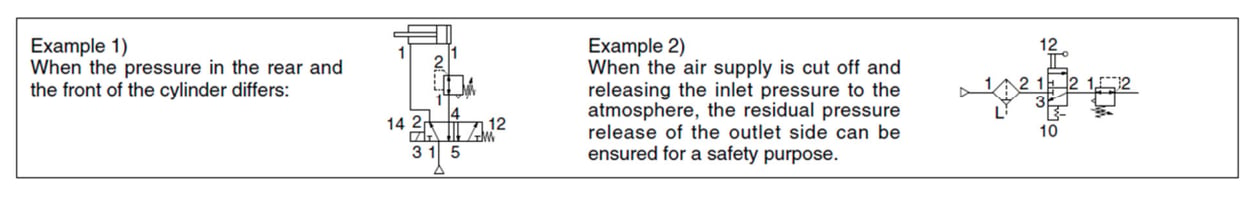

(Example 1 below) It also allows quick and complete release of downstream pressure when the system is shut down for maintenance, etc. (Example 2 below). See the Illustrations below from SMC's catalog literature:

Combining the Features

It's important to note the above features are not mutually exclusive. You can combine these airflow features for specific or niche applications. For example, some regulators have a combination of two of the features above. And it’s possible to have a regulator with all three functions!

How to Choose Your Air Pressure Regulator

Choosing the correct type of pneumatic regulator depends on your application requirements. Relieving regulators are the default choice for most air applications, while non-relieving regulators are ideal for gases you wouldn’t want to be vented into the atmosphere. Right-to-left regulators are helpful when a system is plumbed with the incoming air supply on the right side. Finally, regulators with Backflow Function are used in applications where downstream pressure must be exhausted during machine operation or system shutdown.

Air pressure regulators are crucial in maintaining safe and efficient operation in pneumatic systems. By understanding the different types of pneumatic regulators and their features, you can make informed decisions and choose a suitable regulator for your specific application needs.

If you need pressure regulators for your application, we have the expertise to assist you in selecting the proper regulator for your particular requirements. Contact us today to discuss your application.

Shop Filter/Regulator Combination Unit

|

Configure pneumatic products based on flow, size, shape, materials, functionality, and more. |

Additional Resources

- Explore SMC Air Pressure Regulators

- SMC landing page

- SMC Product Configurator

- SMC Air Boosters

- More Pneumatic Blog Posts

- Contact Us

Airline

Airline

Leave Comment