At the core of any hydraulic system lies hydraulic fluid—a seemingly simple substance with a powerful job and complex composition. Yet, this liquid gold is constantly threatened by contamination, which quietly undermines efficiency and longevity. Understanding what your hydraulic fluid is up against is vital in safeguarding your systems against malfunctions and unexpected downtime. Today, we'll explore different types of hydraulic fluid contamination that can affect your system, disrupt operations, and result in costly repairs or replacements later on. Let's get into it.

Jump to Section

1. Built-In Contamination | 2. Generated Contamination | 3. Air Contamination | 4. Water Contamination | 5. Chemical Contamination | 6. Ingressed Particulate Contamination | Unfiltered Oil Vs. Hydraulic Systems | FAQ & Resources

Explore our range of hydraulic filtration solutions and products today!

Shop filtration & fluid condonation products today!

1. Built-In Contamination

New isn't always clean, especially when it comes to hydraulic systems. The moment you uncrate a fresh piece of hydraulic machinery, you introduce a degree of built-in contamination into your system. Irksome yet inevitable, contaminants like metal shavings, granules, spatter, and even excess assembly grease from manufacturing processes can lurk inside your "new" equipment. These hidden specks weaken efficiency, damage components, and degrade hydraulic fluid—all from the very first operation.

New isn't always clean, especially when it comes to hydraulic systems. The moment you uncrate a fresh piece of hydraulic machinery, you introduce a degree of built-in contamination into your system. Irksome yet inevitable, contaminants like metal shavings, granules, spatter, and even excess assembly grease from manufacturing processes can lurk inside your "new" equipment. These hidden specks weaken efficiency, damage components, and degrade hydraulic fluid—all from the very first operation.

The Fix:

Fill your hydraulic system using a filter cart with an absolute-rated filter made of fiberglass media. The fiberglass media used in these filter/transfer carts should have a Beta Ratio > 200 for 10-micron particles. Servo systems prefer a finer filtration level, like 3 microns. Familiarize yourself with ISO cleanliness levels and ensure your system is in optimal condition.

2. Generated Contamination

.png?width=464&height=261&name=Untitled%20design%20(22).png)

Wear and tear due to operations is unavoidable. The constant motion of hydraulic components against each other generates fine, abrasive grit that infiltrates the hydraulic fluid. This part of the contamination cycle is deceptive. It often starts small and localized, but it can spiral outwards, triggering additional wear as these tiny foes disperse throughout the entire system.

The Fix:

A comprehensive hydraulic system design is the first step to enhance your system's functionality. In addition, regular filter changes can halt this invisible spread and prevent damage to more sensitive areas of the system. With the comprehensive design, you can employ predictive maintenance measures to keep wear-related contamination in check.

Learn more about Predictive Mantine in our blog post, "Maintenance Strategies Explained | Reactive, Preventive & Predictive Maintenance." or learn more about SensoNODE by Parker.

3. Air Contamination

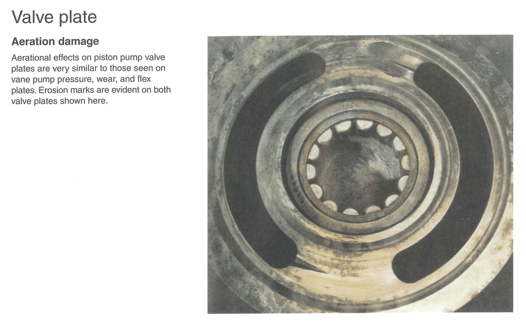

All hydraulic fluid contains air. When air is dissolved in the fluid, there is no problem. However, significant issues arise when air bubbles become captivated in the hydraulic fluid. When pressurized in the hydraulic pump, free air bubbles in the hydraulic reservoir undergo a mini-explosion or implosion. These implosions actually erode the metal surfaces on the pressure side of the hydraulic pump. The main culprits for Aeration are suction leaks, shaft seal leaks, and air ingression from cylinder seals.

See the picture below detailing aeration damage and the reference document from Eaton.

The Fix:

Seal your hydraulic system from the outside world. Minimize fluid exposure during maintenance and regularly assess the efficacy of your seals and piping to maintain the hydraulic integrity every production process craves.

Seal your hydraulic system from the outside world. Minimize fluid exposure during maintenance and regularly assess the efficacy of your seals and piping to maintain the hydraulic integrity every production process craves.

Shop Seals and Seal Kits Today!

4. Water Contamination

Water tends to blend into the hydraulic landscape, capable of hiding in plain sight with its characteristic milky appearance. It's not just its visual giveaway; water wreaks havoc by reducing lubricity, fostering sludge, and catalyzing oxidation and corrosion. The consequences of letting water contamination run rampant can lead to system-wide damage and potential operational shutdowns.

The Fix:

Since water is heavier than mineral oil, the specific gravity of mineral oil is approximately 0.88, and any free water will separate from the oil and settle at the bottom of any reservoir. It’s an emulsion, much like salad dressing. If you stop shaking the container, oil, and water, don’t mix. If your hydraulic fluid appears milky due to water, it is suggested that you turn the unit off and permit the fluid time to separate.

Drain the water from the lowest point in the reservoir until the fluid no longer runs clear. Remember that the rest of the hydraulic system is filled with this milky fluid. Run the hydraulic system for another length of time and repeat. Another option is to use a vacuum dehydrator or centrifuge to remove more water from the system.

Water removal elements are an option but only recommended when the bulk of the water is removed. Each water removal component captures only a minimal amount of moisture, making it an inefficient initial choice.

|

Did you know Airline can provide a comprehensive filtration program that regularly monitors fluid contamination?

|

5. Chemical Contamination

The very fluids we trust to power our systems can be the source of their downfall. Chemical contamination is often overlooked, arising from the natural degradation of hydraulic fluid. High temperatures can accelerate this process, leading to the degradation of critical oil properties, accelerating wear, and causing a domino effect within your system.

The Fix:

Follow hydraulic fluid manufacturers' guidelines. Regular changes and oil analysis help prevent chemical contamination.

Learn "How To Take A Hydraulic Oil Sample" in our blog post or watch our video.

6. Ingressed Particulate Contamination

The final piece of the contamination puzzle is particulate matter from the dirty world outside. This type of contamination is best identified as the foreign bodies that defy your hydraulic system's carefully designed protective barriers. It's the dirt, the dust, the debris that, left unmanaged, can wreak havoc on your finely tuned machinery.

The Fix:

Maintain a meticulous environment during maintenance, keep seals leak-free, and avoid introducing foreign particles into the system. Regularly check vulnerable points and implement robust maintenance protocols to keep the particulate invaders at bay. Suppose these methods cannot keep up with the operating conditions. In that case, installing an offline filter (kidney) loop is recommended to maintain the proper ISO cleanliness code required by the system components.

Learn more about Predictive Mantine in our blog post, "Maintenance Strategies Explained | Reactive, Preventive & Predictive Maintenance."

Unfiltered Oil Vs. Hydraulic Systems

Contaminants in hydraulic systems are not a question of 'if' but 'when.' By knowing their types and sources, you’re equipped to take proactive measures to safeguard your operations.

A clean hydraulic system is a productive one, and its maintenance starts with awareness and action. Don’t wait for contamination to undermine your system’s performance. Understand what you’re up against and take the steps to protect your assets.

|

Hydraulic Filtration Solutions and Products!

Shop Today!

Learn more about our Solutions!

|

Resources:

- Shop Filters Today

- Learn more about Hydraulic Systems and Components

- FLUID CONDITIONING RENTAL UNITS

Leave Comment